Features

- Small size for high density mounting

- Up to 5000VAC Dielectric strength

File No.:E75887

File No.:R 50215857

Contact Ratings

| Contact Arrangement | 2A, 2B, 2C |

|---|---|

| Contact Resistance | ≤100mΩ(1A 24VDC) |

| Contact Material | AgSnO |

| Contact Rating (Resistive) | 8A 250VAC 8A 24VDC |

| Max. Switching Voltage | 440VAC/300VDC |

| Max. Switching Current | 8A |

| Max. Switching Power | 2000VA |

| Mechanical Life | 1×107 operations |

| Electrical Life | See more details at “safety approval ratings” |

Characteristics

| Insulation Resistance | 1000MΩ (at 500VDC) | |

|---|---|---|

| Dielectric Strength | Between coil & contacts | 5000VAC 1min |

| Between open contacts | 1000VAC 1min | |

| Between contacts sets | 2500VAC 1min | |

| Operate time (at nomi. volt.) | ≤10ms | |

| Release time (at nomi. volt.) | ≤5ms | |

| Humidity | 35% to 85% RH | |

| Operation temperature | -40°C ~ +85°C | |

| UL Class B/F | Insulation System Class B/F | |

| Shock Resistance | Functional | 98m/s2 |

| Destructive | 980m/s2 | |

| Vibration resistance | 10Hz to 150Hz 10g/5g | |

| Unit weight | Approx. 13.5g | |

| Construction | Flux Tight Type, Sealed Type | |

Notes:

1) The data shown above are initial values.

2) Please find coil temperature curve in the characteristic curves.

Ordering Information

| SPR | F | 2C | 8 | DC24 | K – | E |

|---|---|---|---|---|---|---|

| Model | F:Class F Blank:Claas B | Contact arrangement: 2A=2 Form A 2B=2 Form B, 2C=2 Form C | Contact Rating: 8=2 Form 8A | Coil Voltage | Pin Distance:K=5mm | E:Flux Tight Type Blank:Sealed Type |

Notes:

1. PC board assembled with dust cover type and flux tight type relays can not be washed and/or coated.

2. Dust cover type and flux tight type relays can not be used in the environment with dust, or H2S, SO2, NO2 or similar gaseous environment etc.

Coil Data at 25°C

| Nominal Voltage VDC | Operate Voltage (Max.) VDC | Release Voltage (Min.) VDC | *Max. Allowable Voltage VDC | Coil Resistance Ω±10% |

|---|---|---|---|---|

| 5 | 3.5 | 0.5 | 6.5 | 62 |

| 6 | 4.2 | 0.6 | 7.8 | 90 |

| 9 | 6.3 | 0.9 | 11.7 | 203 |

| 12 | 8.4 | 1.2 | 15.6 | 360 |

| 24 | 16.8 | 2.4 | 31.2 | 1440 |

| 48 | 33.6 | 4.8 | 62.4 | 5760 |

| 60 | 42.0 | 6.0 | 78.0 | 7500 |

| 110 | 77.0 | 11.0 | 143.0 | 25200 |

Note:

“*Max Allowable Voltage”: The relay coil can endure max allowable voltage for a short period time only.

Coil

| Coil Power | DC:400mW (60V、110V:480mW) |

|---|

Safety Approval Ratings

| UL&CUL | N.O./N.C.:8A 250VAC, 6×103OPS N.O./N.C.:8A 24VDC, 6×103OPS |

|---|---|

| TüV | N.O.:8A 277VAC/240VAC, 85°C, 6×104OPS N.C.:8A 277VAC/240VAC, 85°C, 1×105OPS N.O.:8A 24VDC, 85°C, 1×105OPS N.O./N.C.:8A 277VAC/240VAC, 85°C, 8×104OPS N.O./N.C.:8A 24VDC, 85°C, 5×104OPS |

NOTES:

1. All values without specified temperature are at 25°C.

2. The above lists the typical loads only. Other loads may be available upon request.

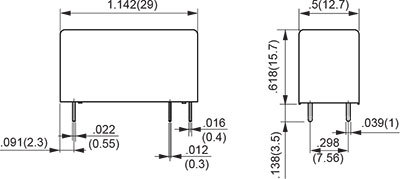

OUTLINE DIMENSIONS, WIRING DIAGRAM AND PC BOARD LAYOUT. Unit: inch(mm)

Outline Dimensions

2A

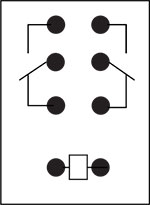

Wiring Diagram

(Bottom view)

2A

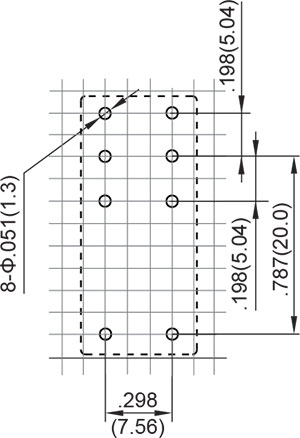

PCB Layout

(Bottom view)

2A

Outline Dimensions

2B

Wiring Diagram

(Bottom view)

2B

PCB Layout

(Bottom view)

2B

Outline Dimensions

2C

Wiring Diagram

(Bottom view)

2C

PCB Layout

(Bottom view)

2C

* The tolerance without indicating for PCB layout is always ±0.1mm.

Unless otherwise specified tolerances are:

| ≤1mm | >1mm and ≤5mm | >5mm |

| ±0.2mm | ±0.3mm | ±0.4mm |

PACKAGING SPECIFICATION

| BLISTER BOX | OUTER CARTON | OUTER CARTON SIZE |

|---|---|---|

| 50PCS | 1000PCS | L375mm*W220mm*H245mm |

APPLICATION GUIDELINES

Automatic Soldering

* Flow solder is the optimum method for soldering.

* Adjust the level of solder so that it does not overflow onto the top of the PC board.

* Unless otherwise specified, solder under the following conditions depending on the type of relay.

| Preheat time 20°C-100°C | Rising slope 20°C-120°C | Decreasing slope Peak-150°C | Welding temperature 255°C-265°C |

|---|---|---|---|

| 90±5 seconds | <3°C/s | <4°C/s | 3~5s |

Hand Soldering

* Keep the tip of the soldering iron clean.

| Solder lron | 30W or 60W |

|---|---|

| lron Tip Temperature | Approx. 350°C 662°F |

| Solder Time | Within approx. 3 seconds |

* Immediate air cooling is recommended to prevent deterioration of the relay and surrounding parts due to soldering heat.

* Although the sealed type relay can be cleaned, avoid immersing the relay into cold liquid

(such as washing solvent) immediately after soldering. Doing so may deteriorate the sealing performance.

Discard the dropped product